CAT ET4 Communication Adapter, 2025A Diagnostic Tool for Caterpillar Truck/Excavator

106,99$ – 811,99$Price range: 106,99$ through 811,99$

CAT ET4 Communication Adapter, 2025A Diagnostic Tool for Caterpillar Truck/Excavator

Please note: Only the Premium Edition of this item comes with a deluxe plastic packaging box. All other editions are packaged in cardboard boxes by default. If you require a deluxe plastic packaging box, please order the plastic box separately.

Product Type Introduction:

1.Only box, no product (This product includes only a plastic empty box, no ET4 product).

2.1 pcs Ethernet cable (This product is a high-speed Ethernet cable that can replace the standard cable in the standard version).

3.ET4 Std Edition (This is the ET4 standard version, which does not include a high-speed Ethernet cable and uses cardboard packaging).

4.With Ethernet cable (This is an upgraded version of the ET4 standard edition that includes a high-speed Ethernet cable).

5.ET4 kit 2025A with 2022 SIS (This is the ET4 kit that includes a high-speed Ethernet cable and comes with 2023C SIS software installation services).

6.Premium Edition (This is the luxury version, which includes a high-speed Ethernet cable and is packaged in a premium plastic shell. Note: This version does not include software installation services for 2025A).

Please note: The Standard Edition does not include an Ethernet cable. Please be mindful of the different product types!

Ethernet cable function: It performs faster and more stable in running speed compared to standard 9+14pin diagnostic cables. Greatly reduces the waiting time for running and programming. It is very helpful for professional maintenance personnel.

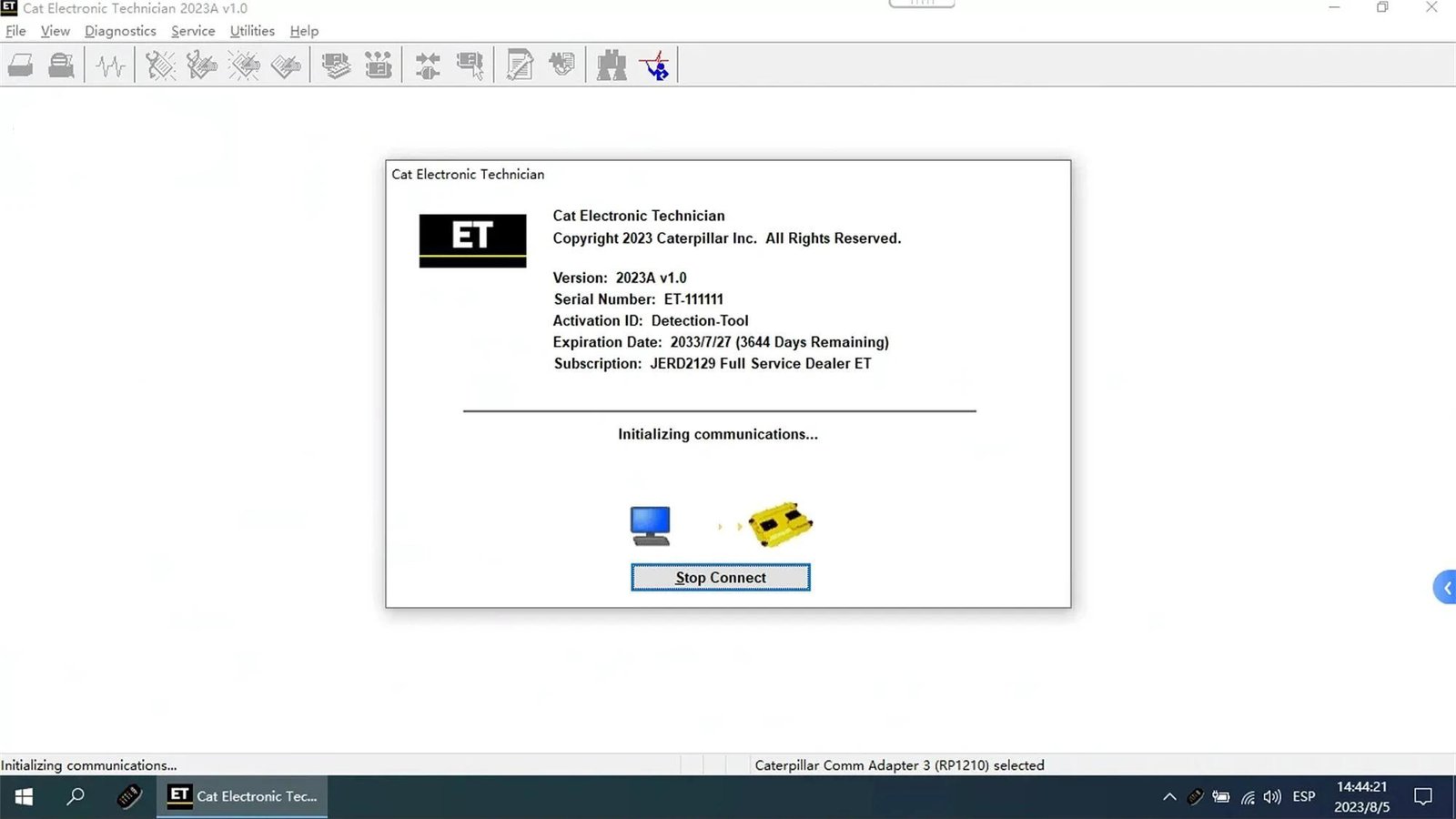

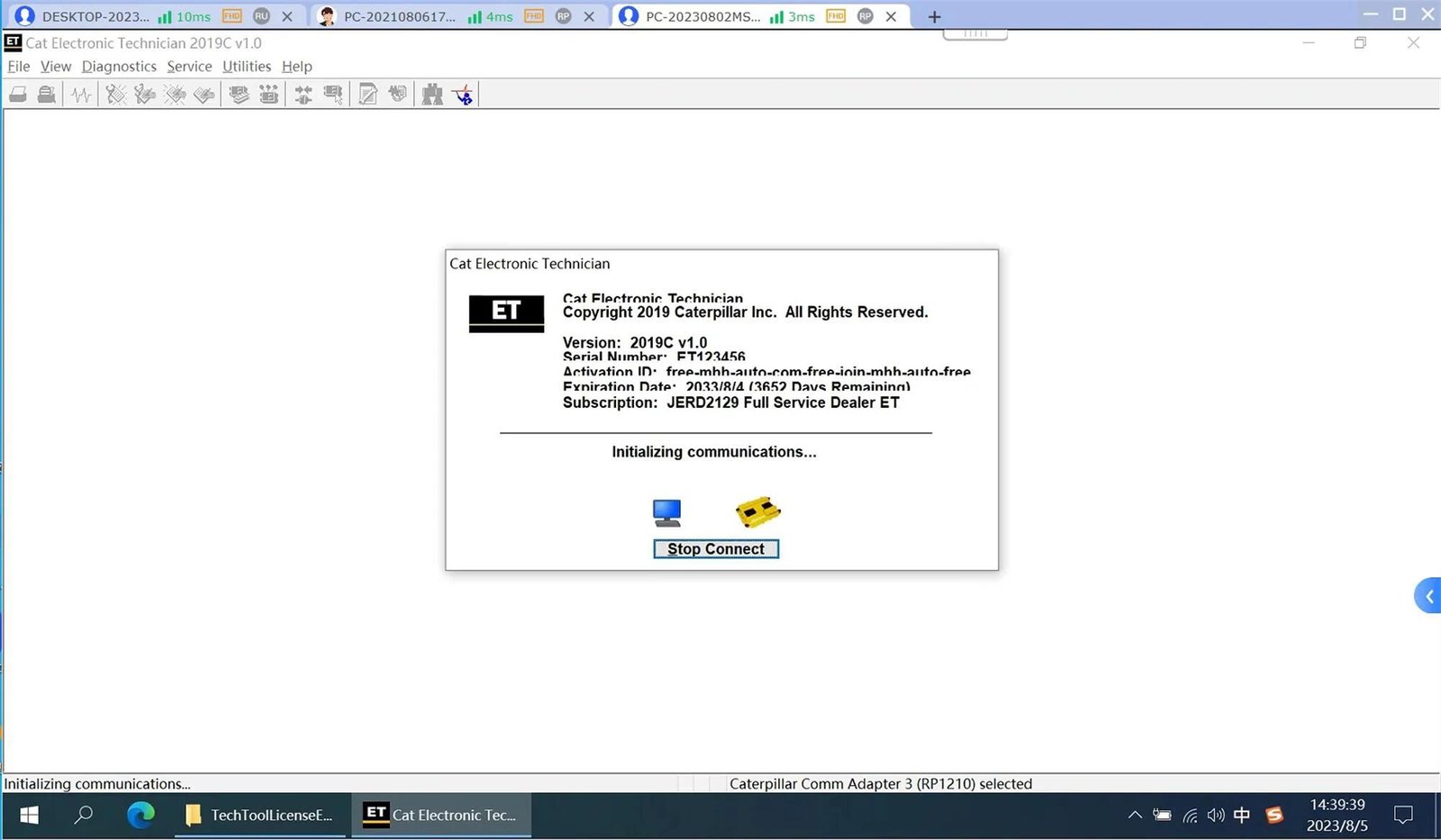

1.Firmware Version : Adapter III. Software Version :2019C,,2023A

2. With Fast USB communication

3. Operate System:Windows7,win8,win10.

4.Compatible Vehicle:For Trucks, Excavators, Air Compressors, Ships, Drilling Rigs

5.Support Multi-Languages:English, Chinese, Danish, French, German, Italian, Japanese, Portuguese, Russian, Spanish.

6.Plug this cable into the port to flash the program 10 times faster than flashing with an adapter.

Description:

Communications Adapter III 478-0235 is the latest generation of the Communication Adapter group,and replaces the for CAT Comm Adapter III 317-7485. This is the only recommended communication device fo rCAT,and the only datalink device that will allow you to properly communicate with a for CAT engine on dual datalinks. This function is needed for some ET (Electronic Technician) functions.

ET Function:

1.Display “Logged Event Codes” to show engine over speeds,High temperatures, fuel consumption, etc.

2.View ECM’s current configuration and change user settings

3.Perform diagnostic tests and calibrations, and calibrate

4.Electro-mechanical and electro-hydraulic components

5.Context sensitive help leads operator through every task forCat ET can perform

6.Data Logger and Data Log Viewer allows recording of ECM signals for delayed troubleshooting capability.

Functionalities Shows all operating conditions that cause high repair costs such as:

Over speeds, high temperatures, fuel consumption, transmission shift counts. This can provide awareness to change operator forCat “ET Trainer” is now included in ET Program. It allows Users to train and practice using forCat ET without a Communications adapter or Electronic Control Module (ECM).This is a free feature of forCat ET.

Application range: Suitable for diagnosing all Caterpillar machinery and equipment before 2023, such as trucks, excavators, air compressors, loaders, ships, drilling rigs, generator sets, Atlas drilling rigs, CSR drilling rigs, oilfield equipment and other inspections.Diagnosis of all engines, hydraulic systems and circuit systems of the CAT series

Communication:

Communication:

1. Allows communication between service tools and engine controls using various data links such as J1939/11, DeviceNet (future release), forCAT DataLink, and J1708 (ATA) vehicle networks

2. Flash program allows adapter firmware upgrades as additional features become available

3. Uses J1939/11, high-speed data link (part of ADEM III controls), substantially reducing flash times

4. Automatically selects J1939/11 when flashing the engine (reduces the flash time approximately 80%, from 14 minutes to 3 minutes). Specification:

Specification:

1.ECM Summary screen lists every control module on equipment

2.Being tested and gives information on these modules.

3.Fast hookup and real time display of systems status. Displays ,readings such as rpm, boost, pressures, temperatures, etc. for Easy troubleshooting.

4.Identifies faulty sensors, harness connectors, and system parameters which are out of specification. Allows customers

5.To help dealer identify problems without visiting machine.

6.Identifies intermittent sensors and wiring problems during Machine operation and keeps a record of each one. Showswhen problem occurred and how often it happened.

7.Added information to allow customer to assist dealer in diagnosing and repairing problems. (Troubeshooting Help is not built in with in the program, you will still need go back to books in order to follow a repair description and steps in each Fault Code display within the program).English and metric units of measure integrated help file to easy learn the “How To” around the software.

| Communication Interface | OBD-II,USB,Ethernet |

|---|---|

| Software Update | Yes |

| Hign-concerned Chemical | None |

Be the first to review “CAT ET4 Communication Adapter, 2025A Diagnostic Tool for Caterpillar Truck/Excavator” Cancel reply

Related products

Trucks & Heavy Duty Diagnostic Tools

WABCO Diagnostic Kit (WDI) for Heavy Duty Trailer/Truck Scanner

Trucks & Heavy Duty Diagnostic Tools

Trucks & Heavy Duty Diagnostic Tools

Volvo Vocom 88890300 Diagnostic Interface for Volvo, Mack, Penta Trucks

Trucks & Heavy Duty Diagnostic Tools

JCB Diagnostic Tool for Excavator, Heavy Duty Truck, J1708, Service Master

Trucks & Heavy Duty Diagnostic Tools

Cummins INLINE 7 Data Link Adapter, Diagnostic Tool with Insite 8.7

Trucks & Heavy Duty Diagnostic Tools

Trucks & Heavy Duty Diagnostic Tools

Trucks & Heavy Duty Diagnostic Tools

Reviews

There are no reviews yet.